Concrete stamping (also known as imprinted or embedded concrete) is a decorative concrete stamp technique that involves imprinting concrete patterns, and often colors, using a rubberized stamp, into freshly poured concrete.

By imprinting natural-looking concrete patterns in freshly placed concrete, you can achieve the high-end look of stone or brick pavement applications, often at a lower cost.

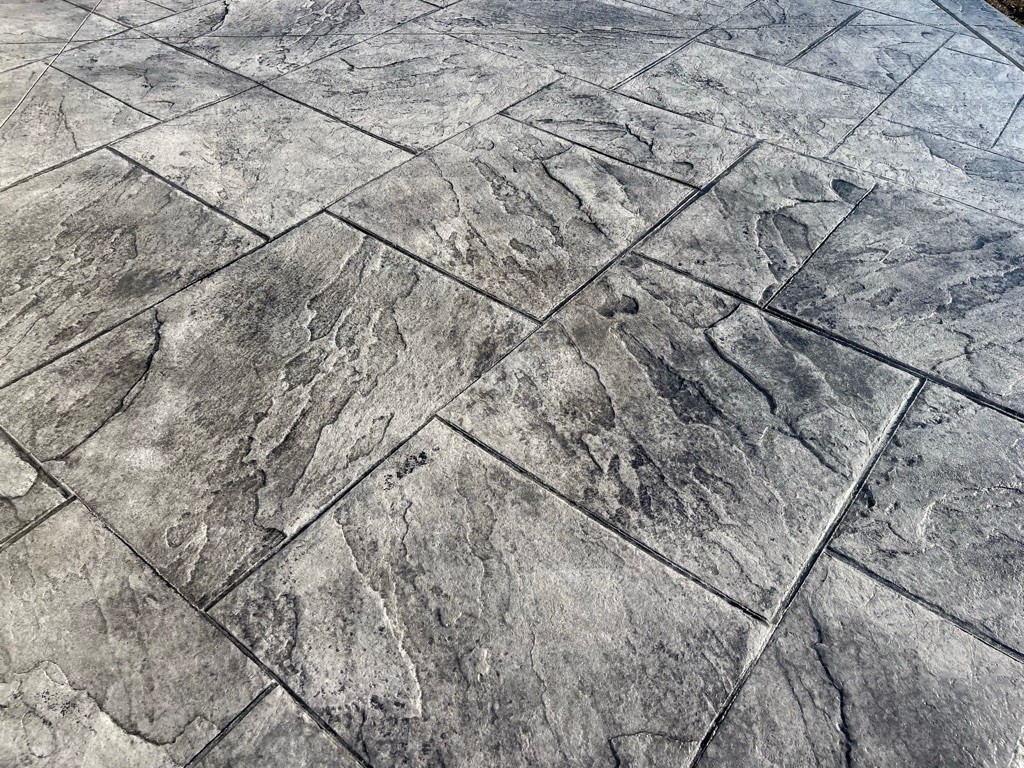

Once the concrete is set, the concrete stamp design is revealed. The concrete surface will look more interesting and attractive by replicating patterns and surfaces such as natural stone, ashlar slate or flagstone, ceramic tile, various brick patterns, and even wood grains.

Where is Stamped Concrete Used?

A large variety of color choices and concrete patterns make it popular for beautifying walking or vehicle parking surfaces just about anywhere. The most common locations are patios, pool decks, and driveways; however, interior options exist too.

Be sure to visit our photo gallery!

From an aesthetic standpoint, it’s hard to beat when it comes to pattern and color options, which are virtually unlimited. Most of our customers find inspiration from their landscape or architecture and choose decorative concrete stamp patterns that blend with existing surroundings. Does your house or building have a brick exterior? Consider adding a border with a running brick pattern, or choose a pattern and color scheme that ties in with your surrounding landscape or driveway.

Exterior Application Ideas

Driveways. Concrete stamped driveways are a popular choice for many homeowners and businesses alike. They are durable and easy to maintain, and they offer a variety of design options. You can choose from a variety of stamps and colors to create a unique look for your driveway. Concrete-stamped driveways are also slip-resistant and can be customized to match your style.

Patios, pool decks, and courtyards. Concrete-stamped patios are a great way to add beauty and value to your home. It’s a trendy choice for patios and other recreational outdoor spaces and one of our most requested services here in Rochester, NY. It is possible to rejuvenate existing concrete surfaces, but an inspection of the existing surface will need to be performed first.

Sidewalks or walkways. Add more beauty to your concrete sidewalk, stamped concrete is a great option. Add curb appeal to your home or business. Customize the color and pattern to match any décor. Additionally, the finish is very durable and can last for decades.

Interior Applications Ideas

Hallways and floors. Yes, you can have custom interior floor finishes too! Why use expensive floor tiles, hardwood, or stone when you can have a more durable stamped finish that looks just like the alternative? Yes, we can even recreate a hardwood floor look!

Countertops. If you’re planning a new or custom kitchen, consider a stamped concrete countertop. Have a kitchen that’s more beautiful and more durable with a concrete stamp and color pattern of your choice.

Bathrooms and entryways. These floors are often highly trafficked and are among the first in your home or office to be in need of replacement. Make them last with a custom concrete stamp pattern floor.

Fireplaces and partition walls. Stamped overlays can be used to enhance partition walls or fireplaces. We also provide stone veneer installation as another option too!

Concrete Stamp Pattern Options

The best part of using concrete stamps is the multitude of options one can choose from. The most popular options include concrete patterns to mimic cobblestone, brick in running bond, herringbone, or European fan patterns, natural stone, flagstone, seamless stone, ashlar slate, wood plank, and random fieldstone.

Concrete stamp patterns are pressed into the concrete even in complex projects with steps. Do you have another pattern in mind? Just ask!

Stamp Pattern Examples:

Coloring Options

Popular color options tend to be grays and earth tones; however, brick patterns are colored in red or russet hues. Colors can be mixed, layered, or even antiqued with stains or tints to create virtually endless possibilities. Multiple colors can also be used within the same project for realistic stone coloration, borders, or a contrasting color pattern.

View our color option page for examples of a large variety of color choices.

Coloring Techniques

Rochester Patio and Landscape prefers to use the dry-shake color hardener application for stamped concrete due to the many benefits achieved by its use, such as increased surface hardening and finish durability. There are also pigments that can be mixed into the wet concrete, but our experience proves the dry-shake color application is the best overall method.

Dry-shake colors are a type of concrete pigment that is applied to the surface of wet concrete. As the name suggests, they are applied in a dry form, and then tamped or brushed into the surface of the wet concrete.

Once the dry-shake color hardener is applied, it reacts with the concrete to produce a hardened surface that is resistant to weathering, staining, and fading.

If you’re looking for a way to add some extra flair to your concrete, stamped concrete is a great option. If you really want to make your stamped concrete stand out, dry-shake color hardeners are a great way to do it.

How Does Stamped Concrete Compare to Other Materials?

When compared to similar options, stamped concrete outperforms other options in many categories:

- Customization: No other surface offers numerous pattern and color choices and complete customization.

- Maintenance: Stamped concrete can last decades with minimal maintenance. Other surfaces such as brick, concrete pavers, or stone require regular maintenance, such as weeding between joints and keeping joints filled with sand.

- Installation: Faster and often less laborious than setting stones or pavers, which can save on labor costs.

- Price: Pouring will usually cost considerably less than installing stone surfaces, and although some lower-end paver options may initially have a lower price, they may end up costing more in the long run for maintenance, repair, or replacement.

Does It Look Fake?

The finished product appears quite realistic! The mats used for stamping are molded from the materials they are designed to emulate. We create a natural-looking finished surface with coloring to match your desired look.

Stamped concrete patterns and color are often more visually stimulating than the real thing. There’s no moss or weed growth between joints too.

Can Stamped Concrete Become Slippery?

Stamped concrete is a textured surface and therefor more slip resistant than conventional concrete. However, just like stone, it can become slippery if a film grows over it or some kind of added post-installation sealer/paint has been applied for some reason.

If stamped concrete is installed in a high-trafficked area, such as an entryway or pool deck, using a non-skid additive or heavier texture can aid in slip prevention. Talk to us if you would like more details.

How Long Will Stamped Concrete Last?

Stamped concrete surfaces may last for decades. The durability resides in a properly installation and periodic maintenance. Stamped concrete stands up to harsh Rochester winter conditions like any other properly installed concrete slab.

Stamped concrete can be more durable than standard concrete, especially if a dry-shake color hardener is used when it is poured. We use a sealer for protection from wear and to make it easier to maintain.

How Do You Install Stamped Concrete?

Several steps similar to pouring a concrete slab are involved, but more importanly, the pattern must be pre-determined and planned well in advance.

Next, we add release agents and color hardeners after the concrete is poured. We then test the concrete before applying the concrete stamp patterns. Finish work, detailing, and cutting contraction joints to finish the project.

Stamping a pattern is done on newly poured concrete. However, existing concrete in usable condition can be covered with a stamped overlay, which gives you the same look as conventional stamped concrete. Contact us about stamped concrete overlays.

Is This A DIY Project?

We don’t recommend it because you only have one chance to get it right. Our team has extensive experience in this field through training and application. Besides, what will you do with all of the tools you spent hundreds of dollars on?

How to Maintain Stamped Concrete

Stamped concrete is a durable and long-lasting process. Maintenance involves simple cleaning and resealing around 2 to 3 years time, but this depends on factors such as vehicle or foot traffic, weather conditions, and other considerations.

Cleaning is simple with a garden hose or pressure washing. A mild detergent and a push broom are all that are needed before resealing.

We use color hardeners and sealers to make the surface stronger and more resistant to abrasion which helps to block stains, water and chemicals.

Does Stamped Concrete Crack?

Stamped concrete is highly resistant to cracking when installed correctly. Surface cracks in concrete can be common and happen over time due to ground freezing and thawing or other factors. Minor crack are usually hard to detect because they will often blend in with the pattern and joint lines. We will assess your layout to determine where and if joint lines are used.

Will the Color Fade Over Time?

Weathering, soiling, and foot/vehicle traffic can degrade the color of stamped concrete over time. Cleaning and resealing will reduce color changes. Even years of neglect or lack of maintenance may be restored by cleaning and resealing.

Does It Withstand Salting/De-Icing In The Winter?

Avoid using de-icing salts on stamped concrete, especially during the first winter after the pavement is installed. Using deicers can cause surface damage. Ammonium nitrate products and ammonium sulfate products are especially harmful because they will actually attack concrete. Sodium chloride and calcium chloride do less damage. We suggest using sand as an alternative for traction.